Operation

DANGER

Electric shock and risk of explosion

If the actuator has not been connected to the protective conductor system (PE), there is a risk of electric shocks caused by a live housing in a fault condition. If the actuator is not connected to the equipotential bonding (PA), there is a risk of electric shocks and explosion caused by static charging of the housing.

- Before starting up the actuator, make sure that it is correctly connected to the protective conductor system (PE) and the equipotential bonding (PA).

- Take measurements to verify the connection to the to the protective conductor system (PE) and to the equipotential bonding (PA).

DANGER

Risk of explosion

In explosive atmospheres, human error can result in an explosion.

- Make sure the type of actuator used meets your requirements for the explosion-protected area. You can find this information on the actuator label.

Ex…: ATEX Zone 1, 2, 21, 22;

Red…: ATEX Zone 2, 22;

In…: not suitable for the explosion-protected area! - As far as possible, avoid working in an explosive atmosphere.

- Disconnect the actuator from the power supply before carrying out any work on it in an explosive atmosphere.

- Make sure that installation and connection work is only carried out by appropriately trained skilled personnel.

- Always work adapted to the ambient conditions.

- Work in active potentially explosive atmospheres must be approved by the operating company.

DANGER

Risk of death due to electric shock and short circuit

Damage to the cabling or incorrect installation can result in an electric shock or short circuit and fire/explosion.

- Make sure the electrical connection and integration of the control unit are only carried out by appropriately trained specialist personnel.

- Please ensure the cables are laid without being damaged. Bear in mind external influences on the cables and use appropriate cable ducts or cable trays.

- Make sure the wiring is done correctly (see circuit diagrams).

- Before commissioning/starting up, make sure all cables and the drive are undamaged.

- Remember the five electrical safety rules:

Unlock

Prevent it being switched back on

Ensure no voltage at all

Earth and short-circuit

Cover or block off adjacent parts that are still live.

WARNING

Risk of crushing and impact

If the actuator starts up unexpectedly, crushing injuries can occur at the connected assemblies.

- Potential crushing points should be considered in the integrator’s risk assessment.

- Check whether additional protective measures are necessary.

- Before beginning work on the actuator, make sure it is completely disconnected from the power supply to prevent an unexpected start-up.

- Make sure the actuator is assembled correctly.

- Check that the actuator fits on the fitting.

WARNING

Risk of crushing and impact

In the event of a power outage, the rotary drives with spring-return mechanism will return suddenly to their initial position. This can result in crushing or impact injuries if work is being carried out on the rotary drive and its connected assemblies at this time.

- Disconnect the power to the rotary drive before starting work. Make sure that nobody is working on the rotary drive or the connected assemblies (e.g. ventilation flaps) at this time.

- Only carry out work when the rotary drive spring is not under tension and is in its initial position.

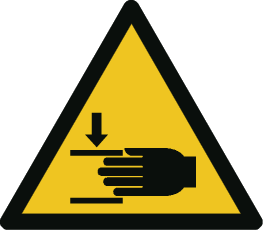

WARNING

Risk of crushing and impact

If the Allen key is inserted, this can result in crushing and impact injuries in the event of unexpected start-up of the drive.

- Before starting work, disconnect the drive from the power supply to prevent an unexpected start-up.

- Remove the Allen key immediately after use.

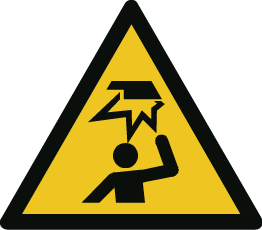

WARNING

Risk of impact

If the drive falls wile work is being carried out, it can hit and injure someone.

- During installation and when dismantling, make sure nobody is located below you.

- During the installation, make sure that the drive cannot loosen or detach itself. The same applies over longer periods, taking into account external influences such as vibration, corrosion etc.

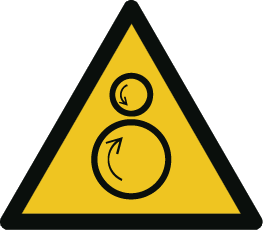

WARNING

Finger twisting

At the open end of the shaft, there can be unexpected rotational movements, e.g. if the rotary drive is accidentally switched on or if the return spring is triggered by a power outage.

- Never stick your fingers into the open end of the shaft.

- Only operate the rotary drive once it is installed.

- Turn off the power to the rotary drive before starting work to avoid it being started unexpectedly.

CAUTION

Possible damage to musculoskeletal system

Working in positions with an adverse body posture can result in orthopaedic injuries.

- Make sure you are working as ergonomically as possible.

- Use appropriate tools, e.g. steps for easy access.

- Wear personal protective equipment: headgear and gloves.

CAUTION

Impact and tripping hazard

If the drive is not positioned carefully, it can pose an impact and tripping hazard.

- As far as possible, avoid installing the drive in the area of footpaths or work areas.

- Position the drive so that it does not cause any risk of tripping or head impact.

- If necessary, provide warning indicators or padding around any potential impact points.