Maintenance

DANGER

Risk of explosion

In explosive atmospheres, human error can result in an explosion.

- Make sure the type of actuator used meets your requirements for the explosion-protected area. You can find this information on the actuator label.

Ex…: ATEX Zone 1, 2, 21, 22;

Red…: ATEX Zone 2, 22;

In…: not suitable for the explosion-protected area! - As far as possible, avoid working in an explosive atmosphere.

- Disconnect the actuator from the power supply before carrying out any work on it in an explosive atmosphere.

- Make sure that installation and connection work is only carried out by appropriately trained skilled personnel.

- Always work adapted to the ambient conditions.

- Work in active potentially explosive atmospheres must be approved by the operating company.

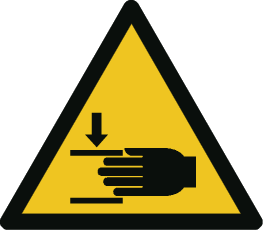

WARNING

Risk of crushing and impact

In the event of a power outage, the rotary drives with spring-return mechanism will return suddenly to their initial position. This can result in crushing or impact injuries if work is being carried out on the rotary drive and its connected assemblies at this time.

- Disconnect the power to the rotary drive before starting work. Make sure that nobody is working on the rotary drive or the connected assemblies (e.g. ventilation flaps) at this time.

- Only carry out work when the rotary drive spring is not under tension and is in its initial position.

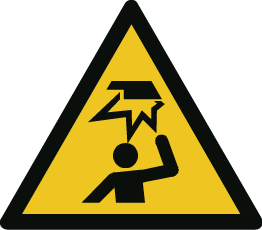

WARNING

Risk of impact

If the drive falls wile work is being carried out, it can hit and injure someone.

- During installation and when dismantling, make sure nobody is located below you.

- During the installation, make sure that the drive cannot loosen or detach itself. The same applies over longer periods, taking into account external influences such as vibration, corrosion etc.

CAUTION

Impact and tripping hazard

If the drive is not positioned carefully, it can pose an impact and tripping hazard.

- As far as possible, avoid installing the drive in the area of footpaths or work areas.

- Position the drive so that it does not cause any risk of tripping or head impact.

- If necessary, provide warning indicators or padding around any potential impact points.

The actuators do not need maintenance in terms of function. Relevant regional maintenance regulations must be complied with in accordance with legal requirements or factory standards.

Drive units are maintenance-free. An annual inspection is recommended. The applicable standards can be consulted for inspecting and servicing electrical systems. Ex devices should only be opened by the manufacturer.

All applicable national and international standards and regulations for Ex areas must be observed. Certified equipment must be installed in accordance with the manufacturer’s instructions. If you use the device in a manner that contravenes that stipulated by the manufacturer, this can impair the safety level of the device. The applicable standards can be consulted for project planning, selection and setting up electrical systems. An Ex e terminal box (e.g. ExBox-...) must be used for the electrical connection. Accessories.

Routine inspections of fire dampers

For periodic inspections, it is important to make sure this takes place with the voltage disconnected (cut off the power supply to the drive). The test button on the ExPro-TT- ... is only for on-site checks on the drive function.